All,

I suspect my mainsheet furling system requires maintenance or replacement. I am looking for some guidance on dos/donts and lessons learned.

Has anyone replaced the furling assembly on a BEN OC 43 (2009) with in-mast US Spar furling system?

-Brendan

Replies to This Discussion

-

If you’re having difficulty with the mainsail furling or unfurling there are a couple of things to check before you start working on the furler itself. The first is to check the car that rides on top of the boom. It has a couple dozen Torlon bearings that ride in a track on the underside of the car. If some or all are missing or dirty they can make it difficult to furl or unfurl the main. Slack off on the out haul and move the car by hand. It should move freely. If not start with SailLube and spray up into the track and move the car to distribute evenly. If you believe you’re missing bearings you can buy replacements from most marine stores. Note however there’s a tool to use to keep them captured in the car. It’s actually a short piece of the track that is mounted on top of the boom. Beneteau should be able to sell you one. It can be almost impossible to keep the balls in the car and slide it back onto the track at the same time.

The second thing to check is the outhaul and furling lines themselves. Older lines accumulate dirt and salt and eventually make it difficult for the line to run cleanly through the sheaves. It’s amazing what a difference new lines can make.

Good luck

Mike

-

-

Thanks for the quick reply, Mike. And the recommendations.

For sure my inhale and outhaul lines are toast and need replacement. I did inspect the boom car, and all is well.

My issue is an issue with the fuller assembly (have isolated to that component). At this point, I haven't been able to inspect the unit for specific issues (i.e. bearings, cracked-furler, etc.). I would have to (as a minimum) remove the furling line to inspect the furling drum screw. To get a full view, I'd have to remove the entire assembly.

There are many posts were issues were related to bearings, or cracked screw, or lines that skipped screw tracks, etc.

My question is...

Have you, or anyone on this board, ever removed the assembly. If so, what happens to the furling foil. Do you let it drop to the foot of the mast, and then raise it again when you go to reinstall when you re-insert the furling assembly.

I'm looking for some lessons learned.

-Brendan

-

-

No I have not had to do any work on the furler assembly. Good luck with it.

-

-

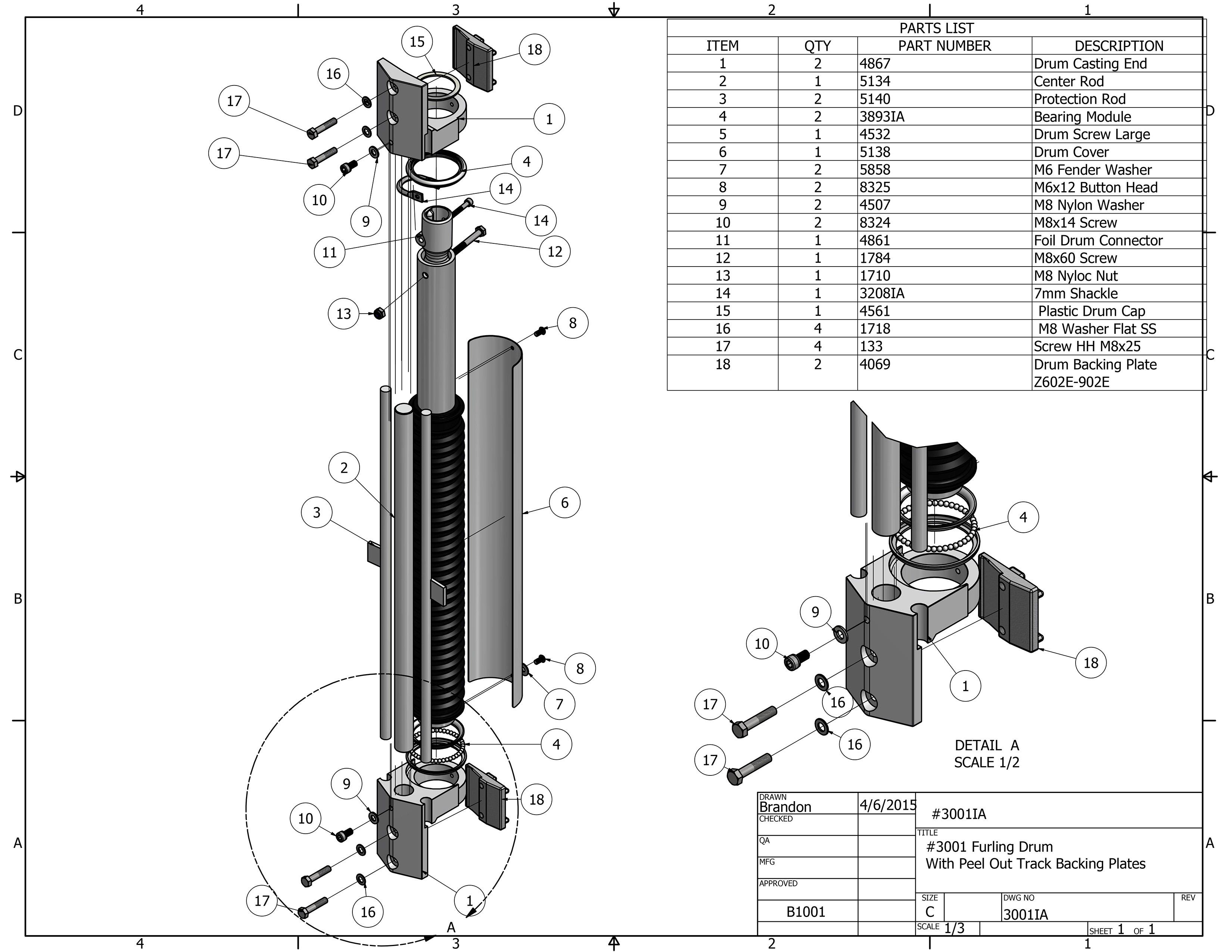

US Spars just got back to me. The entire assembly (P/N 3633) is for sale online at $844.94 USD.

What is not clear to me is how the top foil drum / foil connector (Item #11) attaches to the foil. And what happens to the foil when I remove the entire furling assembly. Does it drop down to rest on the foot of the mast.

-

-

Tie the furling foil off using the inspection ports. Do not let it drop to the bottom. Also, to keep peace with your neighbors, tie a line on to the top swivel and attach to your boom (outhaul) and raise the top furler swivel about mid way up the mast and put tension on it using the line. I had my furler drum out of the mast for rework and a video of my extremely loud foil banging around in the mast (before the tie-off trick) wound up on you tube by one of my frustrated dock mates.

Sam

B43,2008, Hull #9

-

-

The procedure worked. Thanks. I tied the foil off, as recommended. I was then able to remove the furling system assembly.

Once I inspected the unit, I determined the issue (the furling line had jumped a thread and was acting as a brake, as it pressed against the rear aluminum housing (not sure I would have designed the system that way!)

Good news, I was able to resolve the issue without having to buy and replace parts or the entire assembly. I took the opportunity to replace a worn furling line. I reassembled. Works great.

Now onto the next issue. :)

-

-

Glad to hear you got it under control

-

© 2025 Created by CAN DRAC.

Powered by

![]()